The original brake test meter

In production for almost 100 years

Hand-made precision instrument

Measures deceleration and stopping distance

Portable

DVSA-approved

Easy to use

For vehicle Classes 3, 4, 5 & 7

Description

The Tapley meter is the most recognised international standard decelerometer, and as such is trusted by many leading government authorities around the world to set local brake testing standards. Results of Tapley meter tests are accepted as evidence of braking efficiency in Courts of Law throughout the world.

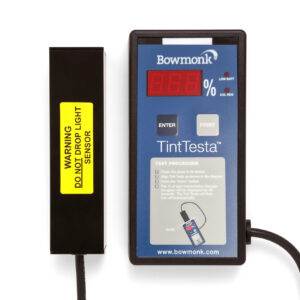

For new customers we recommend that the Bowmonk Brakemeter / Dynometer is ordered instead, but for existing customers the Tapley Brake Test Meter is still available to order with a scale reading in either Metric or Imperial for stopping distance. G force is always shown in %G. The vehicle being tested must be driven at a speed of at least 15 mph (20 mph recommended).

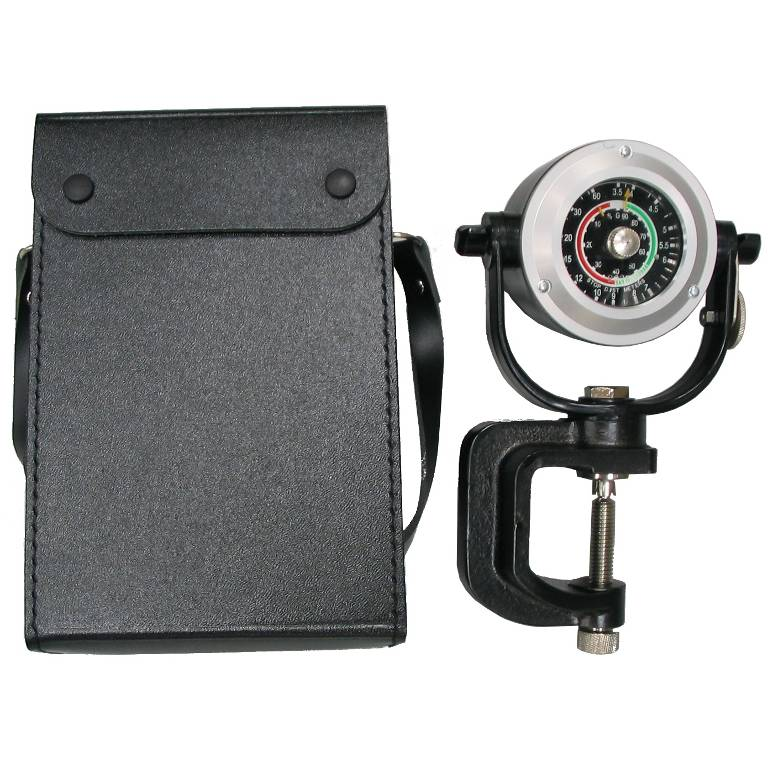

A choice of two mounting mechanisms is available – a floor block or a clamp. All floor block mounting types are supplied with wooden boxes, while clamp mounting types are supplied with carry cases. Please refer to the “Part Codes” tab above for the various Tapley Meter models.

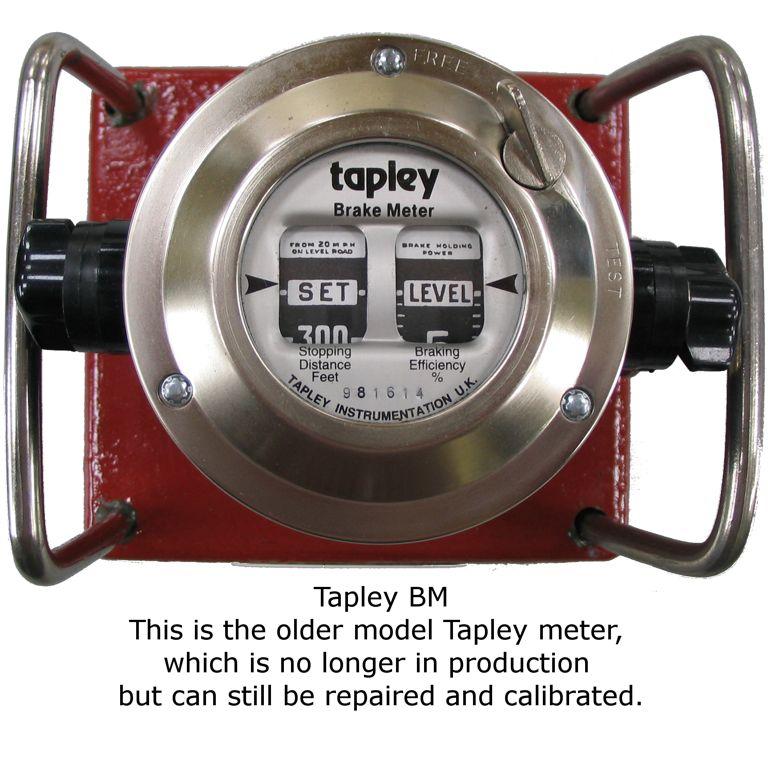

Please note that the final picture in the Gallery tab above shows the original Tapley BM meter – this model is no longer in production but we can still provide repair and calibration services for this instrument.

Advantages

- The Tapley meter is very robust and has low maintenance costs.

- Readily transportable weighing only 10kg complete with its protective casing.

- Simple to operate and needs very little operator training.

- The recommended recertification interval for a Tapley meter is every two years and this is carried out at low cost by us, the manufacturers.

- The Tapley meter has been a recognized international standard decelerometer for almost 100 years and is certified to a standard agreed by the National Physical Laboratory in the U.K.

- Results of Tapley meter tests are accepted as evidence of braking efficiency in Courts of Law throughout the world.

Part Codes

TM5 – Tapley Meter (Feet, Floor block)

Tapley Meter with scale in Feet and a floor block mounting solution. Includes a sturdy wooden carry case.

TM9 – Tapley Meter (Feet, Clamp)

Tapley Meter with scale in Feet and a clamp mounting solution. Includes a leather carry case.

TM15 – Tapley Meter (Metres, Floor block)

Tapley Meter with scale in Metres and a floor block mounting solution. Includes a sturdy wooden carry case.

TM16 – Tapley Meter (Metres, Clamp)

Tapley Meter with scale in Metres and a clamp mounting solution. Includes a leather carry case.

What Is It?

The Tapley Brake Test Meter is a scientific instrument, indisputable in its accuracy as it is based on one of the basic laws of applied physics. It consists of a finely balanced pendulum free to respond to any changes in speed or angle, working through a quadrant gear train to rotate a needle round a dial. To damp out all vibration, the instrument is filled with a special fluid not sensitive to changes in temperature. No maintenance is necessary. The same meter can be used to test all types of vehicles, from heavy trucks and buses to vans and passenger cars. It needs no electrical connections and it’s so portable that you can take the Tapley Meter to the vehicle instead of the other way around.

Test Procedure

To set the instrument for a brake test, start by loosening the two butterfly nuts at the sides of the swivel-mounting bracket. Tilt the head until the main needle (with arrow) is set at 3.5 if the unit is in meters or 13.4 if in feet with the face of the instrument JUST BACK FROM THE VERTICAL. This is important because it can be set with the face nearly horizontal, but it would then be near the end stop and would not move anticlockwise. When set in this manner the butterfly nuts can be tightened again, and the instrument is ready to start the test as pictured under the Gallery tab above (1st image).

With the main needle set, the recording needle (without arrow) should be turned clockwise by means of the chrome knob in the middle of the dial until it is against the left hand side of the main needle. The vehicle is then driven along a level road at about 20 miles per hour or 30 kph, and the brakes fully applied by means of the foot brake pedal only. When the vehicle has stopped the brake efficiency reading can be taken from the figure shown by the recording needle on the inner brake scale. Stopping distance readings are taken from the outer scale figures. A similar reading should now be taken from a lower speed using the handbrake only.